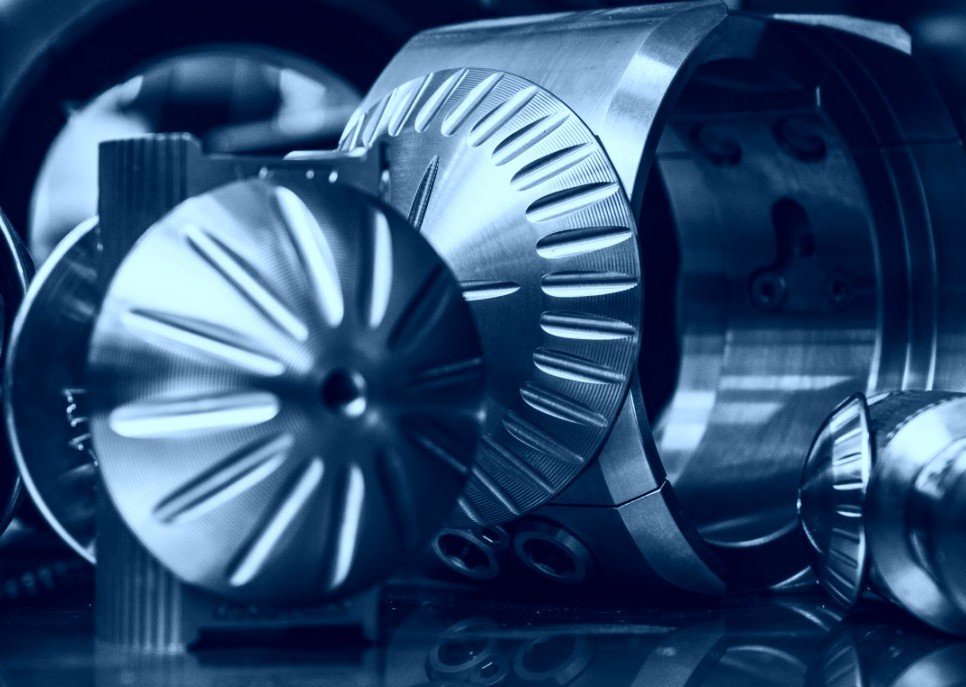

Probe’s I-Wheel Conveyance Optimization technology uses low-friction ballistic-grade bearings that reduce tool string drag along the borehole wall, allowing deployed tools to reach extended deviated depths, reducing the need for – or improving performance efficiency of – standard conveyancing methods such as coiled tubing and tractors.

Available in many sizes for cased hole and open hole, I-Wheel has multiple applications. Because both “in line” or “over-body” configurations are available, I-Wheels ensure tool string length can be kept at its shortest where “rig up” height can be a major factor in wellbore access.

With its rugged, ballistic-grade design, I-Wheel safe to deploy in all wellbore environments and perforating operations.

Most major wireline service companies and independents rely on I-Wheel technology to deploy tools in tortuous and deviated wells. Hundreds of runs have been executed for applications in offshore, onshore, remote fields and HPHT environments. I-Wheels are used extensively in the Middle East, Far East, West Africa, Gulf of Mexico, Mexico, and the UK-Norwegian North Sea.

I-Wheel will be show-cased by Probe on Booth 3063 at this year’s OTC from May 1-4 at Houston’s NRG Center.